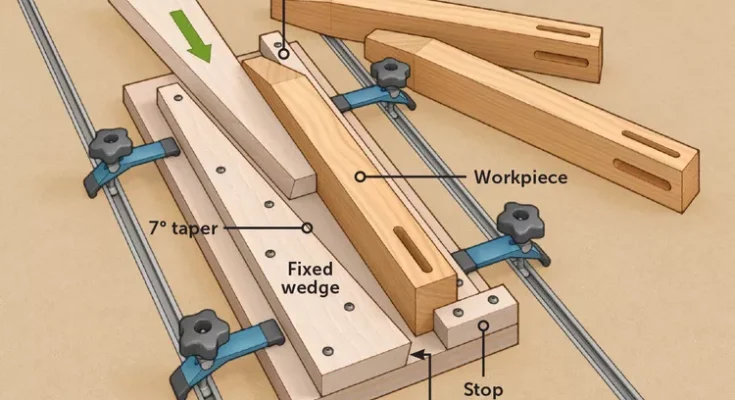

Wedges came in handy when I needed a jig to repeatedly cut accurately positioned mortises in table legs using my CNC router.

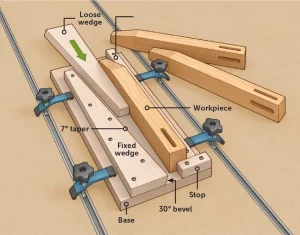

The illustration shows the key components of my clamping jig and how they’re assembled. I started with a 3/4″ plywood base. From a wide board, I cut two wedges by making a tapered ripcut at 7° with the blade tilted to 30°. I fastened one wedge to the base, leaving room for hold-down clamps on the bed of my CNC. A fence and stop locate the workpieces for consistent cuts.

With the workpiece against the stop and fence, slide the loose wedge until it contacts the workpiece and fixed wedge. A couple of light taps with a mallet jam the wedge in place to secure the workpiece.

This quick, secure clamping setup proves so handy that I find myself using it other places, including on my workbench and drill press.